Application Of Shot Peening & Blasting

-

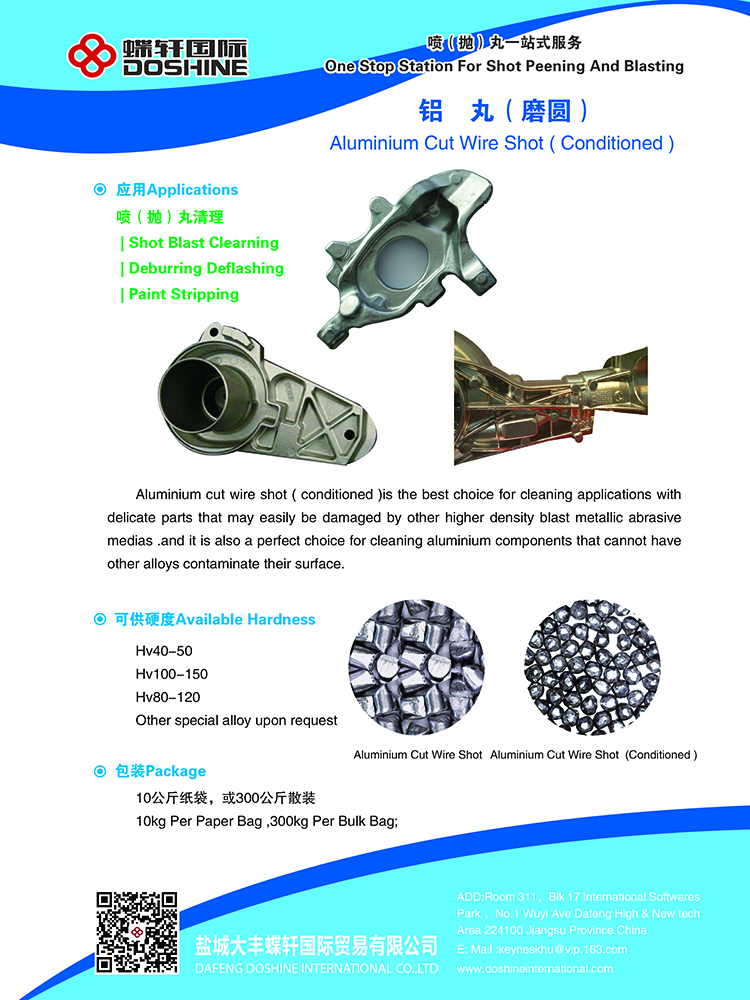

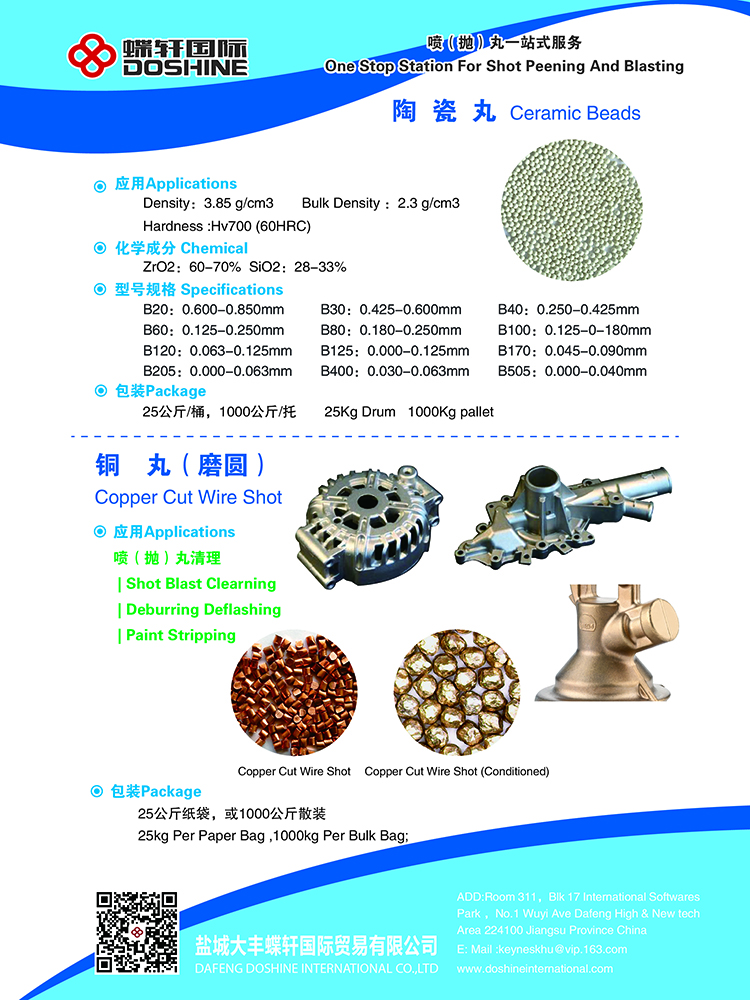

There are numerous applications of cut wires shot to "clean" metallic pieces :

· in foundries, for the de-sanding and cleaning of pieces.

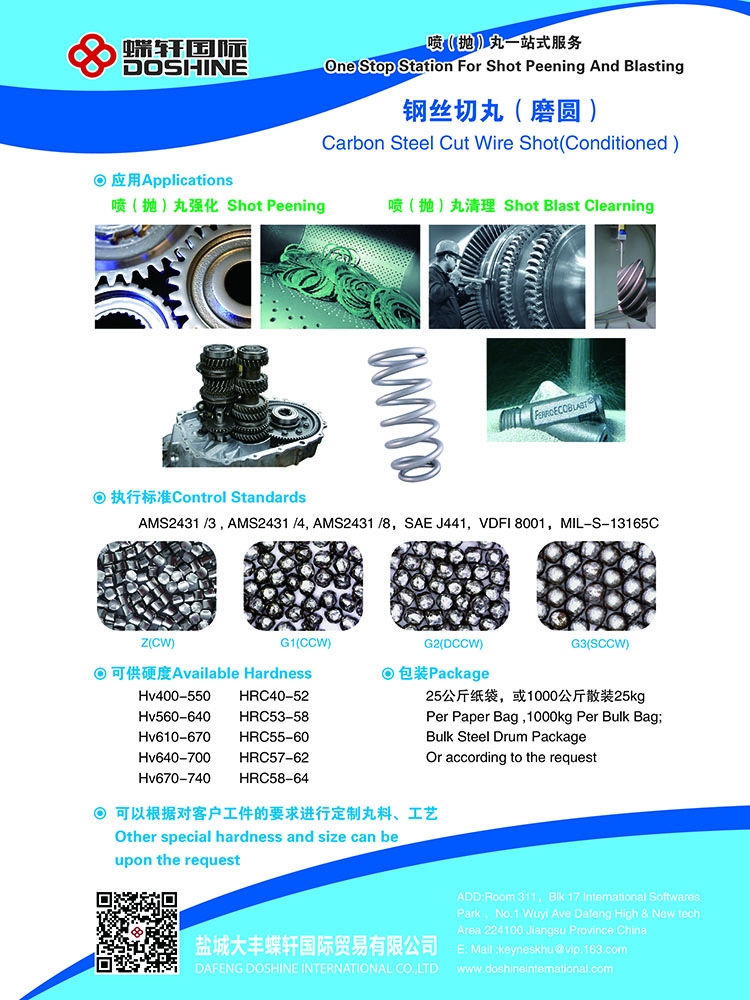

· in the steel industry for the de-scaling of sheet metal, billets, profiles.

· in metal construction, for the preparation of surfaces before painting or metallization.

· shot peening, or prestressed abrasives, the shot demonstrates more efficiency and innovation again.

Indeed, this process strengthens the subject pieces (springs or gear-boxes) considerably as they are subjected to intense fatigue, and gives a good cost/performance ratio!